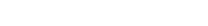

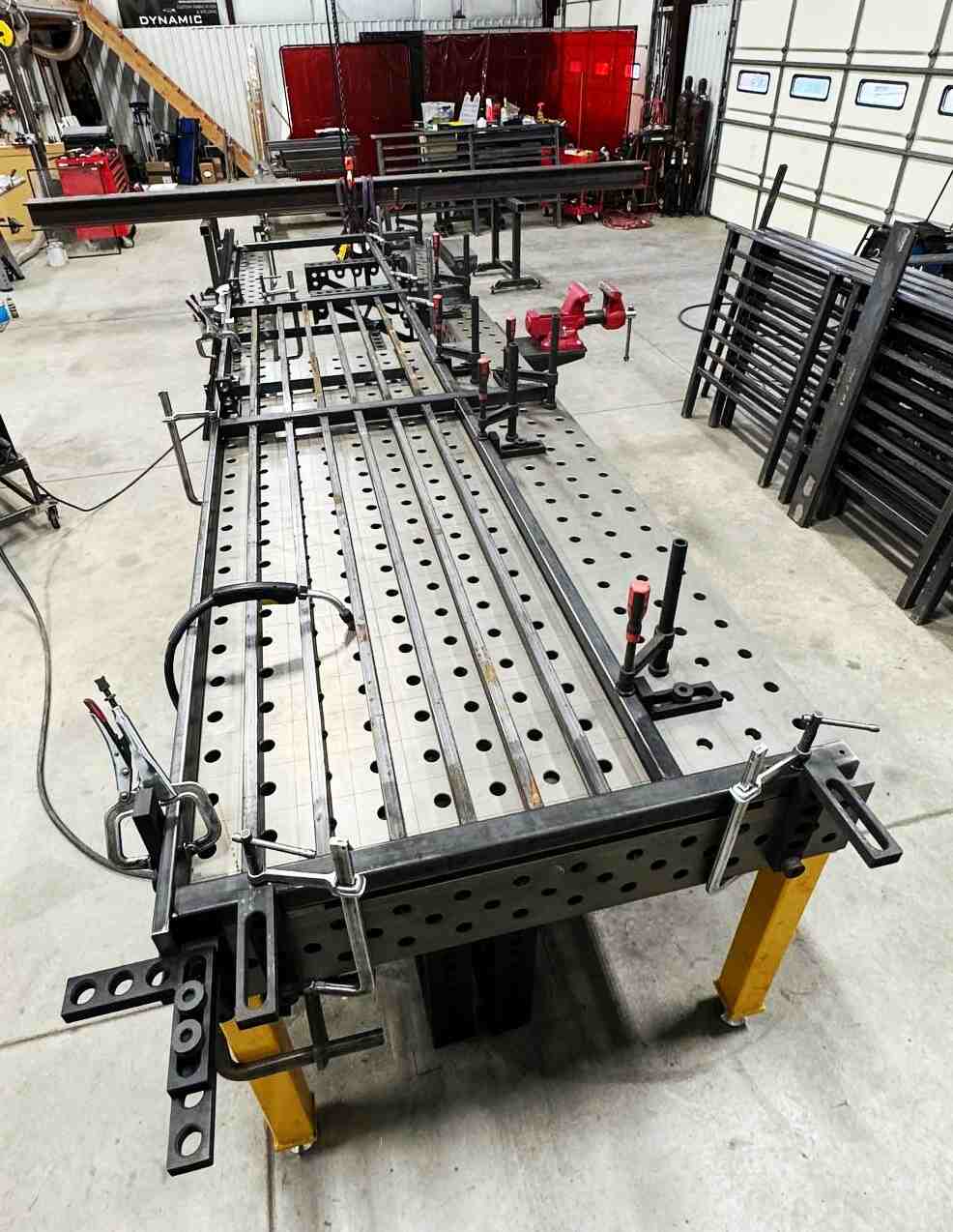

For industries where frame welding demands precision and repeatability, SWJIG 3D welding tables offer the perfect solution. Engineered for versatility and durability, SWJIG’s modular welding tables allow fabricators to quickly set up, adjust, and complete complex frame assemblies with exceptional accuracy. Whether for automotive frames, industrial machinery, or structural steel frames, SWJIG tables help streamline welding workflows and improve product quality.

Each SWJIG 3D welding table features a precision-machined surface with nitrided treatment, providing excellent resistance to wear, corrosion, and welding spatter. The modular grid design, compatible with Siegmund System 16, System 22, and System 28, allows fabricators to use a wide range of locating angles, clamps, bolts, and fixture kits for flexible positioning and secure holding. This adaptability makes SWJIG tables ideal for frame welding, where parts must remain perfectly aligned throughout the welding process.

For industries embracing robotic welding or automated frame welding systems, SWJIG 3D tables integrate easily, supporting faster cycle times and improved consistency. From metal fabrication shops to automotive production lines, manufacturers benefit from reduced setup times, improved weld accuracy, and higher throughput.

With proven performance at industry events like Essen Fair Shanghai, SWJIG continues to set new standards in frame welding solutions. As a trusted China welding table supplier, SWJIG helps businesses worldwide achieve superior quality and efficiency in their welding operations.

Please feel free to contact us if you are interested:

Email: info@swjig.com